Our Industrial designers are always creating and executing design solutions for problems of form, usability and physical ergonomics of industrial or commercial products. As we continue improving the functionality or usability of a product, our main objective is improving the product's marketability and even production. Some of the processes commonly used in our product designing department begin with market research, sketching, comparative product research, model making, prototyping and testing. Our vision as designers in a world of product concept development, is to add value and quality to industrial and commercial markets by improving the usability, developing more appealing products and could be benificial in lowering production costs.

Siliware Concepts also bridges the gap between prototype and manufacturing with our Manufacturing Services. We have a large network of contract manufacturers that include injection molding, precision screw machine parts in brass and Stainless Steel, and CNC production. Our approach is assisting our clients with all areas of manufacturing including competitive quoting, custom tooling and molding, full run manufacturing with quality assurance that designed products meet optimal standards. If your not looking for high qauntity manufacturing and need a short production run – from a single piece to a few hundred items, rapid manufacturing is a great option allowing fully functional items that can be used immediately. Rapid manufacturing is a relatively new process, made possible by vast improvements in resins and materials used for the process. Whatever concept designs or fabrication needs are required, Siliware Concepts has the tooling and molding capabilities to meet your production manufacturing needs.

Siliware Concept engineers and our prototyping specialists seek to understand the limitations of prototypes to exactly simulate the characteristics of general intended designs. Whether an idea or product concept, our equipt facilities and partnering companies test and trial new designs to enhance precision functionality by system analysts and users.

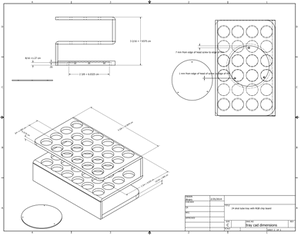

With the advances in computer 3D modeling it has become easy in reducing the high prototyping design costs. Building a full design is often expensive and time-consuming, especially when repeated several times figuring out what the problems are and how to solve them. Our Prototyping specialists are highly skilled and trained in general fabrication techniques that can help bridge between concept designs and the fabrication of prototypes reducing costs through optimization and refinement.

Our company is commited to keeping and continuing business realtionships with our clients and our market distributors. One of our most important departments in our establishment was marketing. We have established close relationships with successful market branding agencies. Our approach to the final product design and marketing process, is guided by our clients and their concept ideas. By developing products that reflect the changes and developments in the marketplace, we aim to create brand products that will appeal to market consumers. Our goal is providing a complete solution that gets your product into retail stores and the hospitality industry by capturing the attention of consumers you target. These important elements used by our company, focuses on a variaty of different marketing strategies. Our marketing department begin with a few but effective solutions we have integrated for a successful product. By emphasising on a few requirements like brand building and positioning, package designing, market research and competitive analysis,

our team can now engage its nationwide team of sales representatives to promote our client’s new and innovative products throughout multiple distribution channels.